P2 Clutch problem

P2 Clutch problem

Hi All

I have recently replaced the clutch friction plate on my 10 and have a problem, I have too much travel on the clutch pedal now before it starts to disengage ; I say starts to disengage because I cannot get enough movement on the clutch arms to disengage it completely, obviously I need some more movement on the clutch arm however there is no more adjustment on the cable and in any case the clutch operating arm travels up to the arm holding the end of the cable nearest the bell housing so it seems it could not travel any more

The new clutch plate was slightly thicker than the old one, I replaced it as a matter off having the engine out and assuming it had not much life left, and the springs were loose

Has anyone had the same issue and if so how did they overcome the lack of travel on the pedal to disengage the clutch, bearing in mind the clutch arm is traveling near enough its full arc before starting to apply pressure on the spring arms to disengage the clutch

Mike Evans suggested turning the woodruff key around on the clutch arm to allow more travel, has anyone done this ?

I don't really want to take the box out again

One thing I did not do was check the height of the clutch spring arms, however I was working on the assumption that everything was fine before so leave well alone

I am a little confused with this any help would be appreciated

Regards

Mike

I have recently replaced the clutch friction plate on my 10 and have a problem, I have too much travel on the clutch pedal now before it starts to disengage ; I say starts to disengage because I cannot get enough movement on the clutch arms to disengage it completely, obviously I need some more movement on the clutch arm however there is no more adjustment on the cable and in any case the clutch operating arm travels up to the arm holding the end of the cable nearest the bell housing so it seems it could not travel any more

The new clutch plate was slightly thicker than the old one, I replaced it as a matter off having the engine out and assuming it had not much life left, and the springs were loose

Has anyone had the same issue and if so how did they overcome the lack of travel on the pedal to disengage the clutch, bearing in mind the clutch arm is traveling near enough its full arc before starting to apply pressure on the spring arms to disengage the clutch

Mike Evans suggested turning the woodruff key around on the clutch arm to allow more travel, has anyone done this ?

I don't really want to take the box out again

One thing I did not do was check the height of the clutch spring arms, however I was working on the assumption that everything was fine before so leave well alone

I am a little confused with this any help would be appreciated

Regards

Mike

Re: P2 Clutch problem

The “free” length of a clutch compression spring is 33 m.m. The compressed length is 22 m.. (See photos here : http://wp.me/pXLKy-24b ) Therefor in a correct assembly the maximum travel of the pressure plate can be 5.5 m.m. This happens when the clutch disk thickness is 3/8 “ = 8 m.m Using a thicker plate than that reduces the possible travel. If the toggles are worn there would be not enough travel to release the clutch. Also make sure that the boss of the plate is free to move in the housing.

Unfortunately the only way to guaranty proper clutch operation is to go by the book. You can see an example here: http://wp.me/pXLKy-1Dx

( I also have a special rig to test the clutch and make sure that it operates correctly. Most clutch renewing places have such a rig https://lulisml.wordpress.com/2014/08/18/8407/ ).

Unfortunately the only way to guaranty proper clutch operation is to go by the book. You can see an example here: http://wp.me/pXLKy-1Dx

( I also have a special rig to test the clutch and make sure that it operates correctly. Most clutch renewing places have such a rig https://lulisml.wordpress.com/2014/08/18/8407/ ).

Last edited by luli on Wed Jan 21, 2015 7:06 pm, edited 1 time in total.

Re: P2 Clutch problem

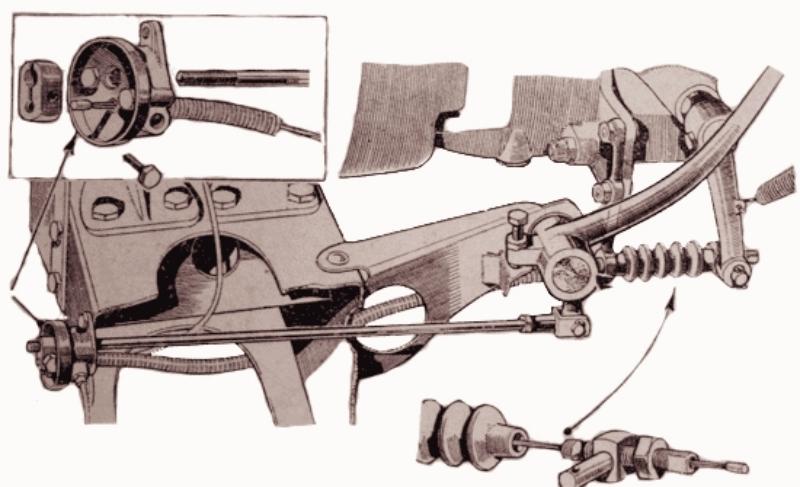

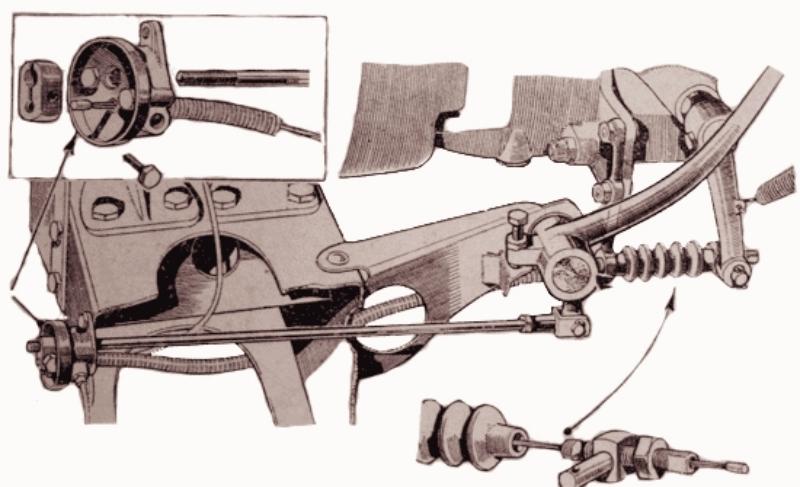

As a last resort you can try the following.

The clutch cable is connected to the bottom of the operation lever. Drill a suitable hole above it, closer to the return spring, and move the connection there. I would start with 1 c.m or so above the original hole. The result will be a longer release bearing travel, and a harder pedal. Some times it works...

Click on the picture to view it; in some browsers use right click and select 'view'

The clutch cable is connected to the bottom of the operation lever. Drill a suitable hole above it, closer to the return spring, and move the connection there. I would start with 1 c.m or so above the original hole. The result will be a longer release bearing travel, and a harder pedal. Some times it works...

Click on the picture to view it; in some browsers use right click and select 'view'

Re: P2 Clutch problem

Thanks for the advice Luli that sounds feasible, I really don't want to take the box out again if I don't have to

Obviously a small increase in the clutch plate thickness makes a lot of difference to the clutch operation on these cars, I wanted to gather some ideas from other members before I made a decision on what method I used to get over the problem, thanks for your help in this

Regards

Mike

Obviously a small increase in the clutch plate thickness makes a lot of difference to the clutch operation on these cars, I wanted to gather some ideas from other members before I made a decision on what method I used to get over the problem, thanks for your help in this

Regards

Mike

Re: P2 Clutch problem

Luli, Having thought about the advice to connect the cable further up the clutch operating arm I don't think this would work as the clutch arm is fully forward to the rear of the car when the clutch pedal is depressed and not able to full release the clutch, I am of the opinion that if the clutch operating arm can be reversed it would then arc in the opposite direction making it point to the front of the car instead of the back, then it would require longer travel to release the clutch, the return spring eye would be in the opposite side to where it is now but it would not be difficult to drill a hole and mount it on the opposite side

I wont get chance to try this until the week end, I will report any success or not

Mike

I wont get chance to try this until the week end, I will report any success or not

Mike

Re: P2 Clutch problem

Last edited by luli on Fri Jan 23, 2015 9:18 am, edited 1 time in total.

Re: P2 Clutch problem

Thanks Lula

I have time to look at the options today so I will see if that will work , thanks for the taking the time to reply and the information

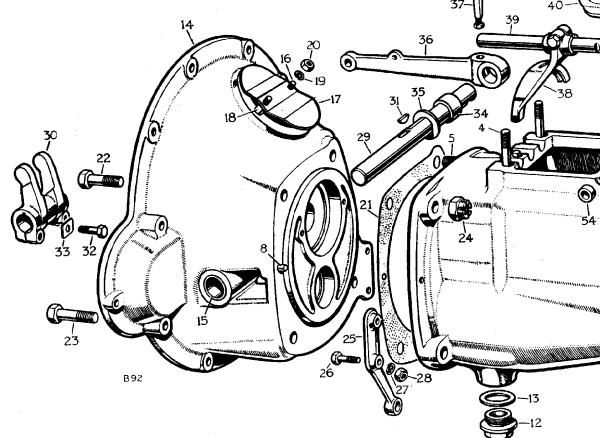

Are you getting your pictures from the partd manual ? They seem more detailed than that

Thanks again

Mike

I have time to look at the options today so I will see if that will work , thanks for the taking the time to reply and the information

Are you getting your pictures from the partd manual ? They seem more detailed than that

Thanks again

Mike

Re: P2 Clutch problem

Hi

Having given this some thought I decided to add some packing to the bracket that supports the clutch cable attached to the bell housing, this in turn allowed the clutch operating arm to come further forward therefore allowing the clutch to disengage completely, I used some aluminium flat plate approximately 2mm thick, drilled holes through them and installed some longer bolts to allow for the increased thickness, I used 5 of these allowing 10 mm of extra movement on the clutch operating arm, obviously with the clutch cable being flexible an extra 10 mm slack did not matter

Problem solved

Mike

Having given this some thought I decided to add some packing to the bracket that supports the clutch cable attached to the bell housing, this in turn allowed the clutch operating arm to come further forward therefore allowing the clutch to disengage completely, I used some aluminium flat plate approximately 2mm thick, drilled holes through them and installed some longer bolts to allow for the increased thickness, I used 5 of these allowing 10 mm of extra movement on the clutch operating arm, obviously with the clutch cable being flexible an extra 10 mm slack did not matter

Problem solved

Mike

-

lakesrally

Re: P2 Clutch problem

Looks like a good solution Mike, glad it has sorted your problem.

-

stuartbell

- Posts: 29

- Joined: Sat Dec 13, 2014 8:49 pm

- Location: Isle of Skye

Re: P2 Clutch problem

Mike,

Presumably you would be able to remove the shims one-by-one as the friction plate wears? Or is the metal part of the driven-plate also thicker than a "standard" clutch plate, thus meaning that the clutch will be excessively worn first? I think that I may need to go down this route with my '10, given that there is some play at every fulcrum!

Presumably you would be able to remove the shims one-by-one as the friction plate wears? Or is the metal part of the driven-plate also thicker than a "standard" clutch plate, thus meaning that the clutch will be excessively worn first? I think that I may need to go down this route with my '10, given that there is some play at every fulcrum!

He with the most toys wins....